Hoʻohana ʻia ka Graphite Electrode no ka Corundum Refining Electric Arc Furnace Liʻiliʻi Diameter Furnace Electrodes

ʻĀpana ʻenehana

Mahele 1: ʻĀpana ʻenehana no ka Electrode Graphite Diameter Liʻiliʻi

| Anawaena | Māhele | Kūʻē | Ikaika Flexural | Opio Modulus | ʻO ka mānoanoa | CTE | Lehu | |

| ʻīniha | mm | μΩ·m | MPa | GPa | g/cm3 | ×10-6/℃ | % | |

| 3 | 75 | Electrode | 7.5-8.5 | ≥9.0 | ≤9.3 | 1.55-1.64 | ≤2.4 | ≤0.3 |

| Nipple | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

| 4 | 100 | Electrode | 7.5-8.5 | ≥9.0 | ≤9.3 | 1.55-1.64 | ≤2.4 | ≤0.3 |

| Nipple | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

| 6 | 150 | Electrode | 7.5-8.5 | ≥8.5 | ≤9.3 | 1.55-1.63 | ≤2.4 | ≤0.3 |

| Nipple | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

| 8 | 200 | Electrode | 7.5-8.5 | ≥8.5 | ≤9.3 | 1.55-1.63 | ≤2.4 | ≤0.3 |

| Nipple | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

| 9 | 225 | Electrode | 7.5-8.5 | ≥8.5 | ≤9.3 | 1.55-1.63 | ≤2.4 | ≤0.3 |

| Nipple | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

| 10 | 250 | Electrode | 7.5-8.5 | ≥8.5 | ≤9.3 | 1.55-1.63 | ≤2.4 | ≤0.3 |

| Nipple | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

Mahele 2: Hiki ke lawe i kēia manawa no ka Electrode Graphite Diameter Li'ili'i

| Anawaena | Haawe o keia manawa | ʻO ka Density o kēia manawa | Anawaena | Haawe o keia manawa | ʻO ka Density o kēia manawa | ||

| ʻīniha | mm | A | A/m2 | ʻīniha | mm | A | A/m2 |

| 3 | 75 | 1000-1400 | 22-31 | 6 | 150 | 3000-4500 | 16-25 |

| 4 | 100 | 1500-2400 | 19-30 | 8 | 200 | 5000-6900 | 15-21 |

| 5 | 130 | 2200-3400 | 17-26 | 10 | 250 | 7000-10000 | 14-20 |

Mahele 3: Ka nui a me ke ahonui no ka electrode kalima li'ili'i.

| Anawaena inoa inoa | Anawaena maoli (mm) | Nominal Length | Hoʻomanawanui | |||

| ʻīniha | mm | Max. | Min. | mm | ʻīniha | mm |

| 3 | 75 | 77 | 74 | 1000 | 40 | -75~+50 |

| 4 | 100 | 102 | 99 | 1200 | 48 | -75~+50 |

| 6 | 150 | 154 | 151 | 1600 | 60 | ±100 |

| 8 | 200 | 204 | 201 | 1600 | 60 | ±100 |

| 9 | 225 | 230 | 226 | 1600/1800 | 60/72 | ±100 |

| 10 | 250 | 256 | 252 | 1600/1800 | 60/72 | ±100 |

Noi Nui

- ʻO ka hoʻoheheʻe ʻana i ka calcium carbide

- Ka hana ʻana o Carborundum

- ʻO ka hoʻomaʻemaʻe corundum

- ʻO nā metala kakaʻikahi e hoohehee ana

- Ferrosilicon mea kanu refractory

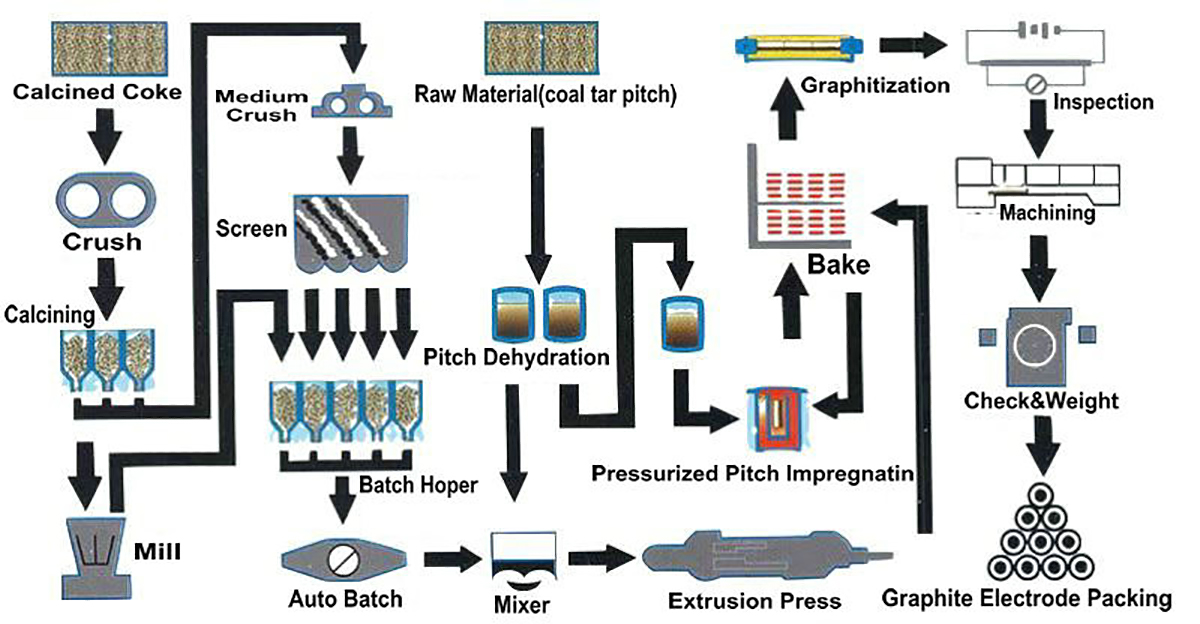

RP Graphite Electrode Production Process

Nā Pōmaikaʻi Gufan

1. Hana ʻia mai nā mea graphite kiʻekiʻe, ua kūkulu ʻia kā mākou mau electrodes graphite diameter liʻiliʻi e kū i nā wela wela a hāʻawi i ka conductivity uila maikaʻi loa. Mālama kēia i kahi kaʻina hana hoʻoheheʻe paʻa a maikaʻi, e hopena i ka maikaʻi o ka huahana a me ka hoʻemi ʻana i ka ikehu.

2. ʻO ka liʻiliʻi liʻiliʻi o kēia mau electrodes e hiki ai ke hoʻomalu pono i ke kaʻina hana hoʻoheheʻe ʻana, e hoʻomaʻamaʻa iā lākou no nā noi e koi ana i ka pololei kiʻekiʻe a me nā hopena maikaʻi. Inā ʻoe e hana ana i nā mea hao a i ʻole ka hoʻomaʻemaʻe ʻana i nā metala, e kōkua kā mākou electrodes iā ʻoe e hoʻokō i ka hopena i makemake ʻia me ka pololei ʻole.

3. ʻO kā mākou mau electrodes graphite liʻiliʻi liʻiliʻi e kūpono i ka nui o nā ʻoihana, e like me ka hana kila, ka hana kemika, a me ka hoʻolei ʻana i ka metala. No ka nui o kāu hana, hiki ke hoʻonohonoho ʻia kā mākou electrodes e hoʻokō i kāu mau koi kikoʻī.

4. Ma ka hana kila, hoʻohana ʻia kā mākou mau electrodes graphite liʻiliʻi i loko o nā kapuahi uila, kahi e hana nui ai lākou i ka hana ʻana i ke kila kiʻekiʻe. ʻO ko lākou liʻiliʻi liʻiliʻi e hiki ai ke hoʻomalu pono i ke kaʻina hoʻoheheʻe, e hōʻoia i nā hopena kūlike a me ka hoʻemi ʻana i ka ʻōpala.

5. I ka hana kemika, pono kā mākou mau electrodes no ka hana ʻana i ka calcium carbide a me ka hoʻomaʻemaʻe ʻana o ka carborundum. Pono kēia mau kaʻina hana i ka mālama ʻana i ka wela, kahi e hāʻawi ai kā mākou electrodes me ka pololei loa.

6. No ka hoʻoheheʻe ʻia ʻana o ka metala, hoʻohana ʻia kā mākou mau electrodes graphite liʻiliʻi i ka hoʻoheheʻe ʻana i nā metala liʻiliʻi a me nā mea kanu Ferrosilicon. ʻO ka conductivity maikaʻi o ka graphite e hiki ai ke hoʻoheheʻe maikaʻi i nā metala, ka hopena i ka wikiwiki o ka hana ʻana a me ka nui o ka huahana holoʻokoʻa.